Our range of Hot rolled

Hot Rolled

Hot Rolled steel (HR) is steel that has undergone the hot rolling process at a temperature above its recrystallisation temperature. Compared to unprocessed steel, the HR material exhibits greater formability. The hot rolling process converts slabs into coils.

The HR product is available with the surface untreated or dry (HRD) or pickled and oiled (HRPO) to produce a cleaner surface.

The HR product is available from John Tainton in gauges ranging from 1.5mm to 20.0mm.

QUICK STOCK® available:

2000mm x 1000mm

2500mm x 1250mm

3000mm x 1500mm

4000mm x 2000mm

To make a sales enquiry please call 01562 740477 or email jtsales@johntainton.co.uk

Floor Plate

Floor Plate steel is a hot rolled product that follows the same process as Hot Rolled Dry (HRD) however, the Hot Mill utilises different rolls that imprint a pattern into the surface. This pattern is known as ‘American tear drop’ or ‘Durbar®’ ( a trademark product from Tata steel). Other common names for Floor Plate include Tread Plate, Wear Plate and Checker Plate.

John Tainton are proud to offer S275 floor plate with American Tear Drop patterns; available in QUICK STOCK® sizes or in de-coiled lengths to suit a particular project.

QUICK STOCK® available:

2500mm x 1250mm

3000mm x 1500mm

3mm On The Plane (4.5mm Overall)

4.5mm On The Plane (6mm Overall)

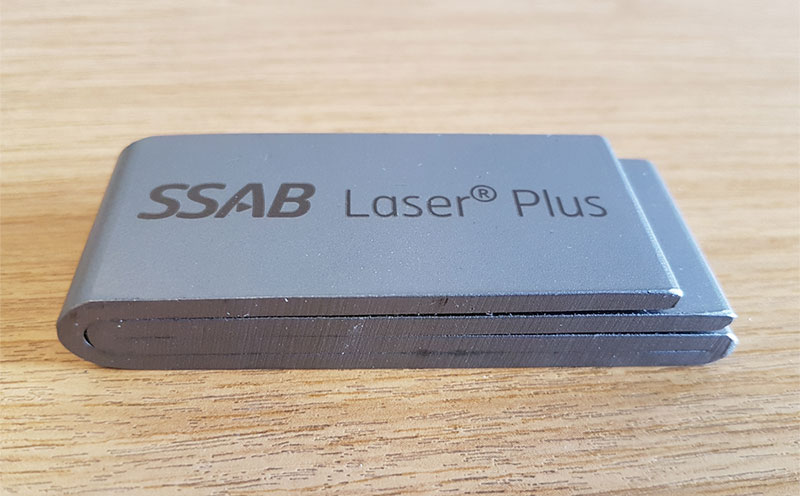

SSAB Laser® Plate

John Tainton is pleased to announce we have the license to distribute SSAB Laser® material.

SSAB Laser® is advanced high strength steel offering superior properties for laser cutting, stamping and cold forming. This product is available in an S355K2 C+N (impact tested to -20°C), in addition to high strength, low alloy grades such as S420MC and S460MC (impact tested to -60°C). Gauges available range from 8mm to 30mm.

The benefits of SSAB Laser® are:

- Guaranteed flatness tolerance after laser cutting of 3mm/m (typical values of 1mm/m). This means less rework and no need for levelling/straightening. In addition, a 5-10% increase in sheet yield is achievable due to improved nesting possibilities.

- Unique forming properties – The MC+ products have a minimal internal bending radius of 0mm, offering more freedom in designing modern components. Forming instead of welding is an effective way to cut production costs. Uniform mechanical properties from batch to batch allow consistent, repeatable bending in all directions. SSAB guarantees an inner bending radius of 0-1.5 x the material thickness, depending on strength level and thickness.

- Highest cutting speed – The chemical composition of SSAB Laser® offers optimal conditions for laser cutting. SSAB Laser® can cut at a speed up to 30% faster than conventional steels.

- Reduced galvanising costs – The low silicon content of SSAB Laser® (Si <0.03%) significantly lowers zinc coating costs and offers shorter galvanising times.

COR-TEN®

COR-TEN® is SSAB’s Weathering Steel. It has high corrosion resistance and is available as a cold-reduced or hot-rolled product.

With its anti-corrosive properties, COR-TEN® minimises the need for maintenance and corrosion-prevention treatment. This leads to significantly lower maintenance costs throughout the product lifecycle. The reduced need for corrosion prevention means less use of paint and solvents, making COR-TEN® an environmentally friendly choice of steel. Typical applications are structural components for buildings, transmission poles, bridges and many others.

COR-TEN® is a strong and durable steel, and the rust that provides corrosion protection can last from a few decades to over 100 years.